Cutting Mercedes Boron steel requires specialized knowledge and techniques due to its complex microstructure. Professional training covers material properties, cutting methods, equipment, safety protocols, and authorization processes involving permits and certifications based on local regulations and industry guidelines. Understanding these aspects ensures precision, prevents damage during high-energy processes, and facilitates expert handling of car body repair projects with this advanced alloy.

Mercedes Boron steel, known for its exceptional strength and durability, demands specialized knowledge when it comes to cutting. This article delves into the crucial aspects of safely handling Mercedes Boron steel cutting, emphasizing the need for technical training and professional authorization. We explore the unique properties of this advanced material and the challenges it presents, along with the essential steps required to ensure precise and secure fabrication.

- Understanding Mercedes Boron Steel Properties and Challenges

- Technical Training Essentials for Safe Cutting Processes

- Authorization Procedures for Professional Steel Fabrication

Understanding Mercedes Boron Steel Properties and Challenges

Mercedes Boron steel is a high-performance alloy renowned for its exceptional strength and durability, making it a preferred choice in the automotive industry, particularly for luxury vehicle repair and modern car manufacturing. This advanced material offers unique advantages, such as superior resistance to wear and tear compared to traditional steels. However, working with Mercedes Boron steel cutting presents several challenges that require specialized knowledge.

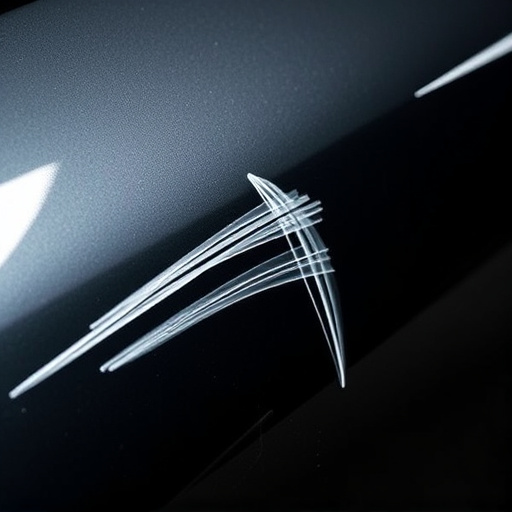

When engaging in tasks like dent removal or classic car restoration involving this steel, it’s crucial to understand its properties. Mercedes Boron steel is known for its complex microstructure, which includes a combination of hard boride particles dispersed in a soft matrix. This unique composition leads to exceptional hardness and resistance but also makes cutting and shaping more demanding. Professionals must employ specific techniques and tools authorized for this material to ensure precision and prevent damage during the cutting process.

Technical Training Essentials for Safe Cutting Processes

Technical training is an indispensable aspect of learning how to safely cut Mercedes boron steel, a high-strength alloy commonly used in modern car collision repair and auto body repairs. This specialized metal requires precise techniques to ensure accurate cuts without compromising structural integrity. The training should cover a comprehensive understanding of the material’s unique properties, including its hardness, toughness, and corrosion resistance.

Proficient operators must learn about different cutting methods suitable for boron steel, such as plasma or laser cutting. They should be taught how to set up and maintain the cutting equipment, selecting appropriate settings for optimal performance while minimizing the risk of damage or deformity. Safety protocols are paramount, encompassing personal protective equipment (PPE), proper ventilation, and understanding potential hazards associated with high-energy processes like plasma cutting.

Authorization Procedures for Professional Steel Fabrication

Authorization for professional steel fabrication is a stringent process designed to ensure safety and quality standards, especially when dealing with materials like Mercedes Boron steel. Before engaging in cutting or shaping this advanced metal, technicians must obtain the necessary permits and certifications. This involves understanding local regulations and industry guidelines, which often include rigorous training programs specific to the material’s unique properties.

The procedure typically starts with an application process where professionals demonstrate their expertise through written exams, practical assessments, and possibly even workshops. Once approved, they are issued with a license or authorization to work on car body repair projects involving Mercedes Boron steel, ensuring that any fender bender or auto repair near me is handled by qualified hands.

Mercedes Boron steel cutting requires a meticulous approach due to its unique properties. Adequate training and authorization are essential to ensure safe and precise fabrication processes. By understanding the challenges and adhering to strict protocols, professionals can harness the full potential of this advanced material, making Mercedes Boron steel a reliable choice for demanding applications. Remember, proper training equips individuals with the skills needed to navigate the intricacies of cutting this specialized metal, ultimately contributing to its successful integration in various industries.